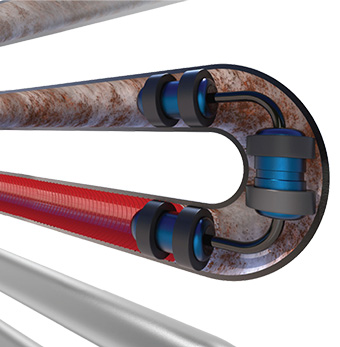

Using conventional NDT methods to inspect coils in process fired heaters, furnaces and steam generators is challenging. Quest Integrity overcomes these challenges by offering a comprehensive solution with its Furnace Tube Inspection System (FTIS™) and advanced engineering assessment capabilities. FTIS™ is a high-resolution automated ultrasonic inspection technology that quickly and accurately inspects piping coils contained in fired heaters, furnaces and steam generators per API Recommended Practice 573. This technology eliminates the need for scaffolding and confined space entry and is uniquely designed to inspect even the most complex coil configurations such as those containing numerous pipe diameter changes, plug header fittings, tee connections and common headers.

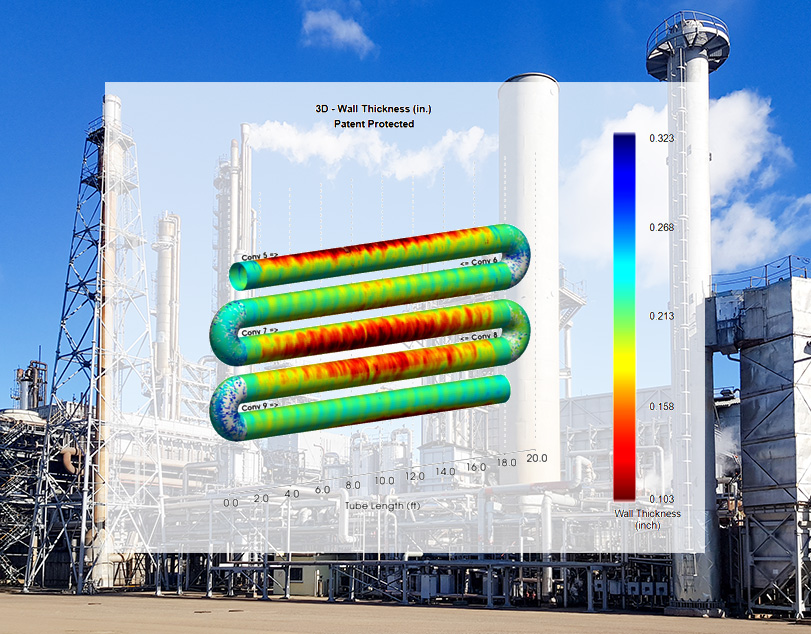

FTIS™ detects and measures existing damage mechanisms such as internal and external corrosion, erosion and pitting, along with deformations such as bulging, swelling and ovality in serpentine and arbor coils, providing owner-operators with a complete and quantitative mapping of a coil’s wall thickness and geometry. These damage mechanisms are quickly identified and quantified in an inspection report.

An onsite preliminary assessment is typically delivered within 24 hours of the inspection. Based on the inspection results, an advanced engineering assessment using the company’s proprietary software, Streamline™, calculates the remaining life and fitness-for-service of the fired heater tubes in accordance to the API 579 / ASME FFS-1 standards. Accurate corrosion rate information helps decrease the risk of failure and helps operators improve run times, which translates to increased fired heater, furnace and steam generator efficiency and reliability.

Read more on the important factors to consider when selecting an inspection technology in Quest Integrity’s paper authored by Tim Haugen, “A Smart Approach to Inspecting Fired Heater and Boiler Coils”.