The typical outcome of an FFS assessment is a “go/no-go” decision on continued operation. Such assessments may also include an evaluation of remaining life or inspection intervals, along with remediation of the degradation mechanism. Quest Integrity has substantial FFS engineering assessment experience and has applied this approach to a wide range of assets. Our technical experts have been heavily involved in developing the API 579-1/ASME FFS-1 FFS standard, and some serve on the committee that maintains this document.

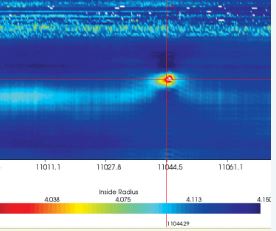

We also provide the industry-leading Signal™ FFS software, which enables end users to perform evaluations ranging from the routine Level 1 to the more in-depth Level 2 and advanced Level 3 remaining life assessment.