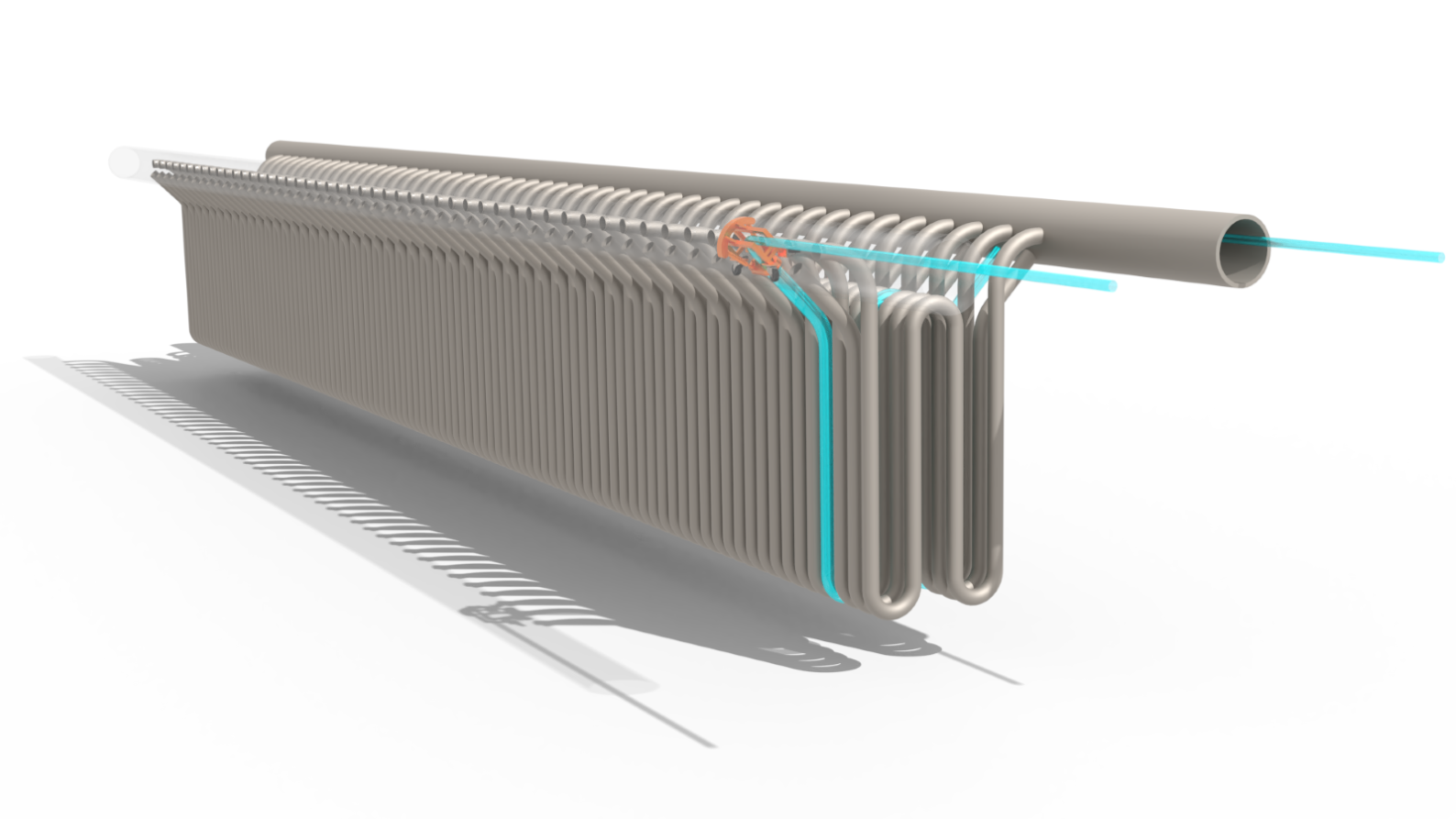

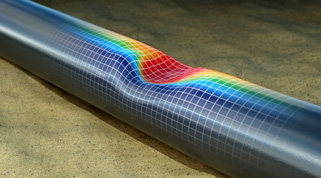

The InVista® ultrasonic (UT) in-line inspection (ILI) bi-directional tool provides single-pass, combined geometry, and metal-loss data with 100% overlapping coverage. Designed to overcome the most demanding wharf- and subsea-ILI conditions, it provides unmatched data accuracy, operational efficiency, and navigational capabilities.

Based on pipeline inspection results, an advanced engineering assessment can be made using Quest Integrity’s proprietary software: Streamline™ Universal Platform. It enables data set(s) from a pipeline to be interlaced with existing data on that same line. Additionally, the Streamline platform calculates the remaining life and fitness-for-service of marine-loading lines in accordance with API 579/ASME FFS-1 standards. Accurate corrosion rate information enables operators to take a proactive approach to reducing the risk of failures, while optimizing casing integrity management.

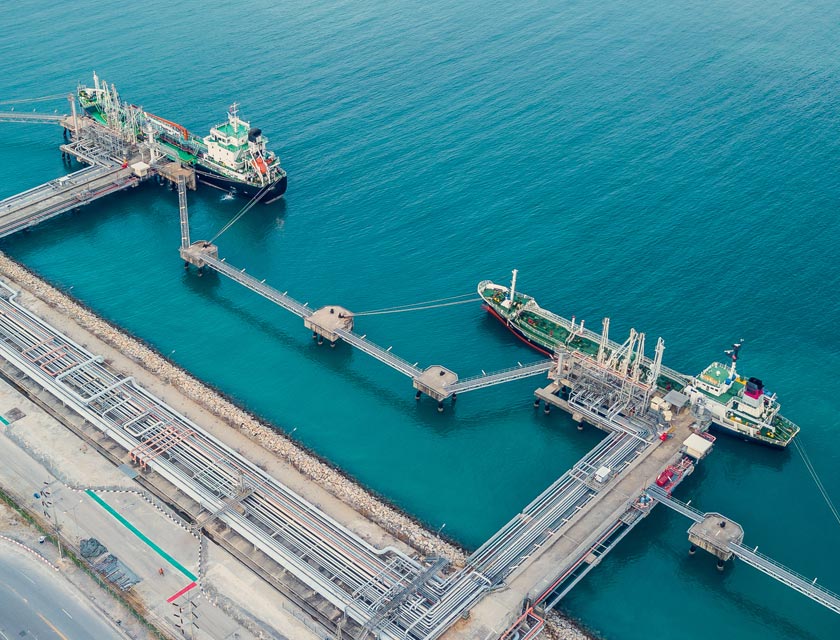

InVista is a self-contained, lightweight, memory-based, and easily transportable tool, making it the ILI answer for 2- to 48-in diameter and dual diameter marine lines. Handheld, InVista requires no lifting machinery, and its bi-directional capability enables it to be loaded, launched, received, and unloaded from a single point.

InVista inspections can be conducted under substantially reduced pressure requirements without permanent modifications to piping systems. It is also capable of negotiating back-to-back be bends with >90° short-radius turns, bore restrictions, step changes, reduced port valves, and limited or missing launcher/receiver facilities.

InVista technology ensures marine-line integrity for operators through efficient and comprehensive inspections that minimize offline status. The technology provides onsite turnaround and rapid data analysis as it relates to flaw locations, enabling real-time operational decisions. InVista inspections never permanently magnetize loading lines, eliminating demagnetization repairs.