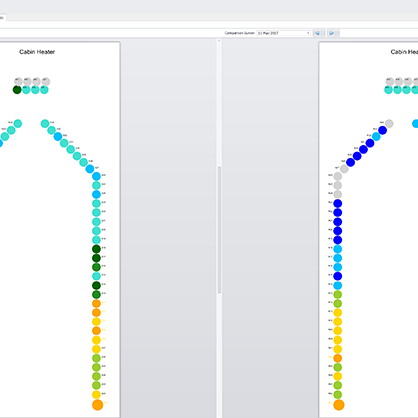

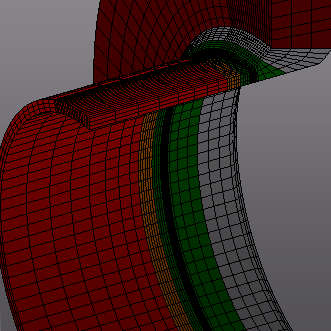

CorrectIR software performs correction calculations to remove common errors from infrared thermometry tube temperature measurements taken with pyrometers or thermal imaging cameras. By utilizing a mathematical model directly tied to the actual furnace geometry, the corrected temperatures are more accurate than conventional infrared measurements.

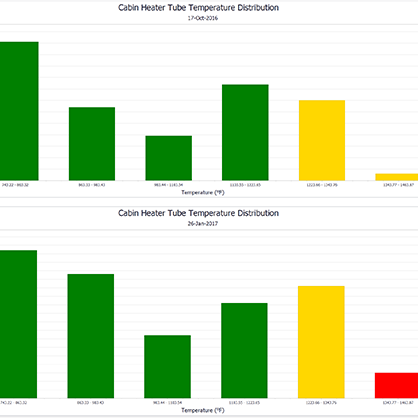

The proven methodology is repeatable and less dependent upon technician interpretation of the thermal images. The corrected temperatures may be used to validate operation within integrity operating windows, manage tube reliability and assess failure risk. CorrectIR uses a database structure to store and statistically compare the measurements with future infrared measurements.

CorrectIR addresses the three kinds of errors that influence infrared (IR) accuracy:

- Environmental Errors (CorrectIR fixes this)

- Instrument Errors (CorrectIR fixes this)

- Human Errors (Quest Integrity training and CorrectIR both fix this)

NextLevelIR: Heater Thermography Auditing

Conventional IR thermometry is subjective, and the way IR corrections are applied is inconsistent. Not knowing the true temperature can lead to improper decisions. With Quest Integrity’s Heater Thermography Auditing (HTA) program, we will provide recommendations that will allow your IR thermographers to produce the most accurate temperature readings. The corrected temperatures can be used to validate operation within IOW, manage tube reliability and assess failure risk.