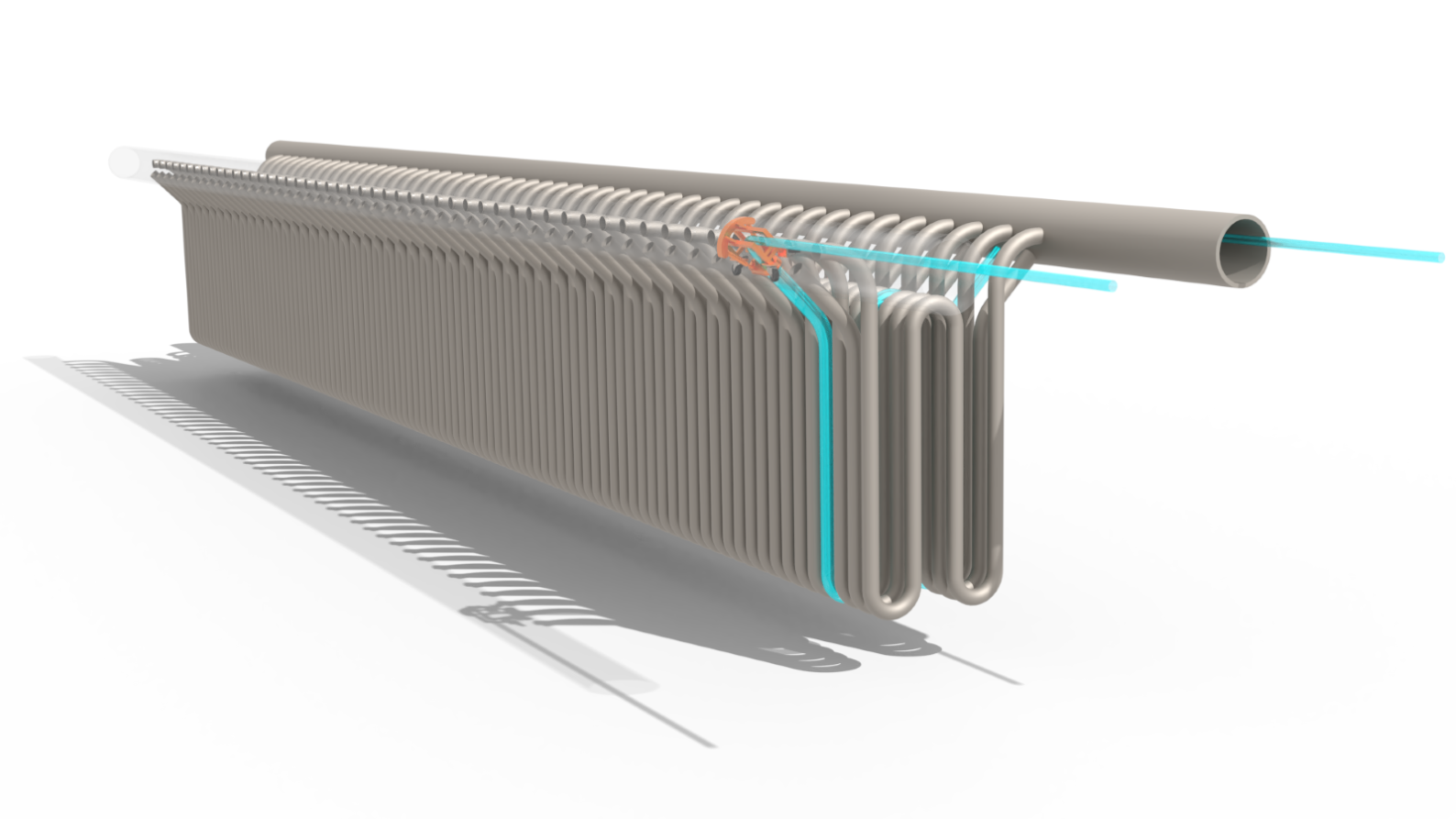

The QWIX ultra-sonic well casing examination tool delivers ultrahigh-fidelity content and graphics through the most efficient collection, analysis, and communication of reliable and informative results of the production casing well barrier element (WBE). QWIX detects and quantifies corrosion affects over time, enabling better well-field risk management.

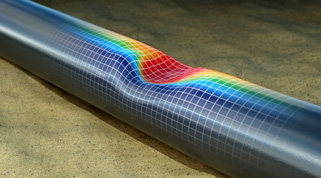

QWIX provides comprehensive data and imagery of casing-wall thickness (WT), with overlapping coverage of geometry and metal loss features. Unlike other casing examination tools with 6 or 8 calipers that take general readings to calculate averages, QWIX takes hundreds of thousands of readings per meter to maximize accuracy.

QWIX owes its deep roots in testing, integrity, and assurance to Quest Integrity, which has developed rigorous and trusted integrity technology and software that provide cost-effective information to optimize productivity and prevent loss of containment.

Based on inspection results, an advanced engineering assessment can be made using Quest Integrity’s proprietary software: Streamline™ Universal Platform. It enables QWIX data set(s) from a well to be interlaced with existing data on the same well. Additionally, the Streamline platform can calculate the remaining life and fitness-for-service of the casing in accordance with API 579/ASME FFS-1 standards. Accurate corrosion rate information enables operators to take a proactive approach to reducing the risk of failures, while optimizing casing integrity management.