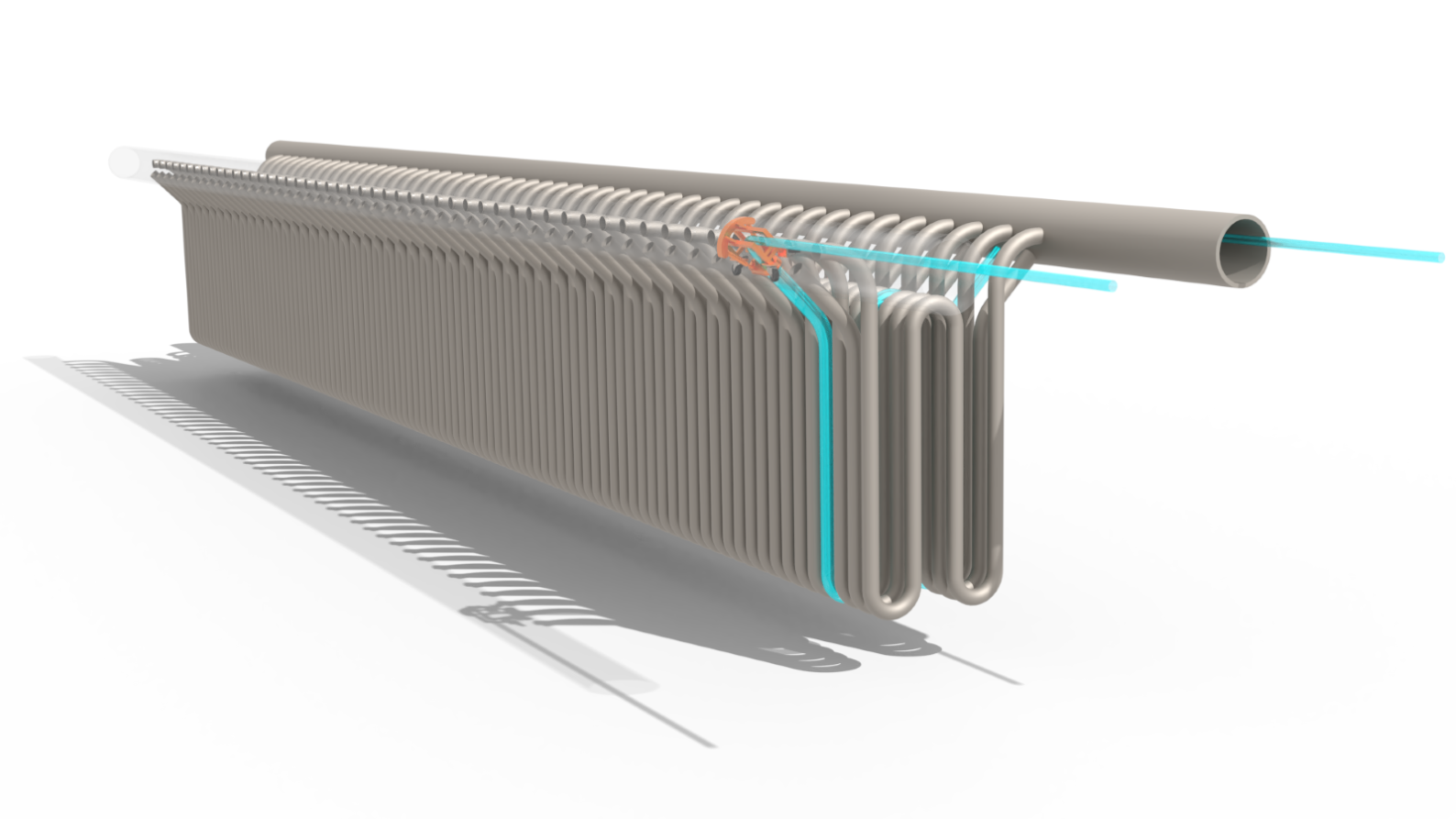

Quest Integrity provides comprehensive inspection solutions powered by intelligent pigging technology and advanced engineering assessment capabilities. The InVista® bi-directional in-line inspection (ILI) tool can provide integrity assessments of piping systems fabricated from austenitic, ferritic, and some non-metallic materials, in dual or multi diameters of 2- to 48-in, including varying pipe wall thicknesses.

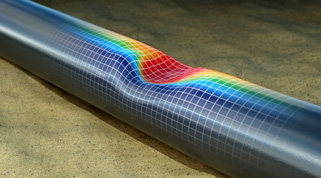

Based on pipeline inspection results, an advanced engineering assessment can be made using Quest Integrity’s proprietary software: Streamline™ Universal Platform. It enables data set(s) from a pipeline to be interlaced with existing data on that same line. Additionally, the Streamline platform can calculate the remaining life and fitness-for-service of pipelines in accordance with API 579/ASME FFS-1 standards. Accurate corrosion rate information enables operators to take a proactive approach to reducing the risk of failures, while optimizing pipeline integrity management.

Following the field inspection and preliminary report, the high-quality ILI data is analyzed for wall loss and anomalies such as corrosion, denting and ovality. Our Streamline software assesses the pipeline’s fitness-for-service and quantifies the extent of metal loss damage. The remaining strength factor (RSF) and reduced maximum allowable operating pressure (MAOPr) are also determined for the complete data set. A final report including the data analysis and assessment results is delivered for each ILI (in-line inspection) project along with the Streamline data viewer.