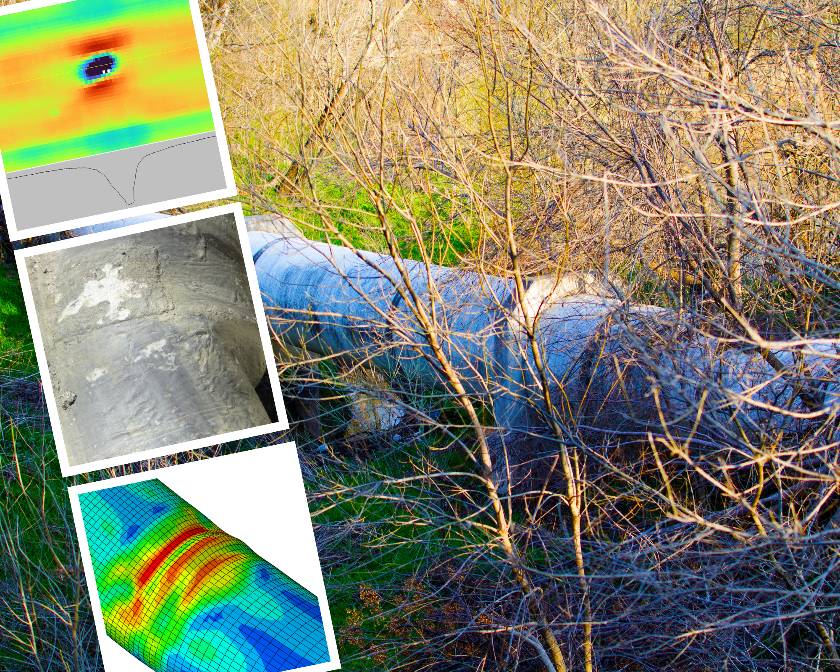

Pipeline crack detection has been identified as one the largest integrity issues operators face today due to the lack of available advanced technology able to adequately detect and size anomalies across all operating pipelines and environments. Cracks in pipelines such as Stress Corrosion Cracking (SCC) and resident manufacturing defects can lead to catastrophic safety and environmental incidents and having the correct inspection solution with reliable data is crucial to making the right call at the right time and avoiding unnecessary incidents.

AQiRE is the next generation of electromagnetic technology (EMAT), engineered to eliminate or reduce pipeline operational risks. The innovative solution provides high resolution in-line inspection for small diameter natural gas pipelines, including those identified as difficult to inspect. The short-body, low drag tool provides superior navigability and is suitable for low-pressure difficult-to-inspect, or unpiggable pipelines.

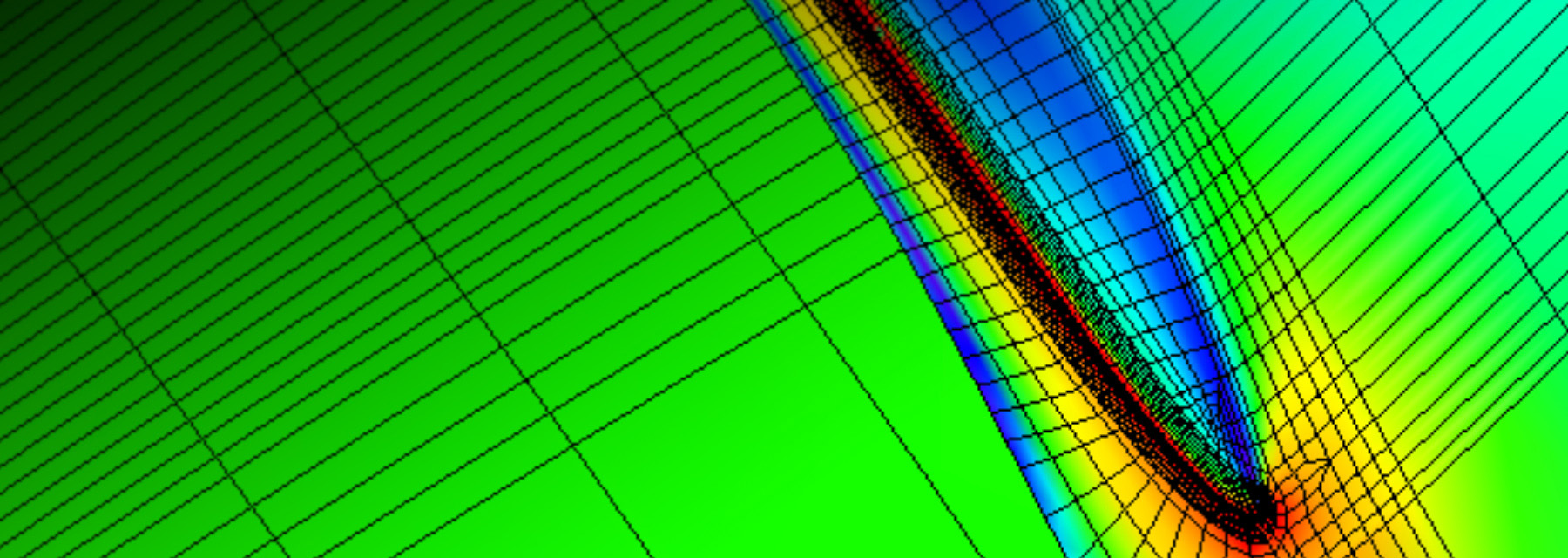

The patented EMAT sensors are enhanced to reduce signal congestion in small diameter pipelines simplifying detection and characterization of flaws and resulting in an improved signal-to-noise ratio. The system’s data acquisition capabilities allow for 100% collection and storage of the raw A-Scan data for improved analysis and discrimination. This method of optimized data acquisition results in zero blind spots, stronger signal returns, and simplified data analysis.