The application of FFS standards means that common damage mechanisms such as corrosion, shell bulging, cracking, and edge settlement no longer automatically require costly repairs. FFS methods and advanced engineering analysis make the most of the standard data collected during required inspections. This approach helps define new requirements when additional inspections are necessary.

Storage Tank Integrity Assessment Solutions

Quest Integrity utilizes decades of experience, multi-phased approaches, and novel solutions to assess tank integrity.

Talk To An Expert

Quest Integrity utilizes decades of experience, multi-phased approaches, and novel solutions to assess tank integrity.

Talk To An Expert

Service Highlights

Storage Tank Integrity Assessment Solutions

- Hydrostatic test exemptions for atmospheric storage tanks following shell and/or floor repairs per API 653 Tank Inspection, Repair, Alteration, and Reconstruction

- Analysis of excessive settlement of Aboveground Storage Tanks

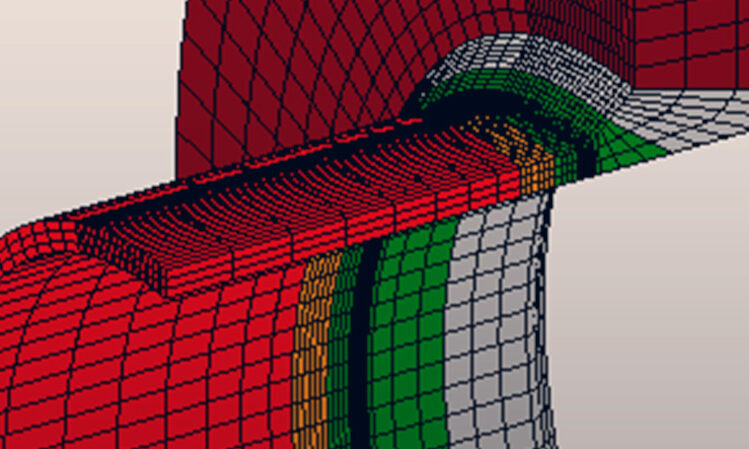

- FFS, including remaining life predictions, considering a wide range of damage mechanisms

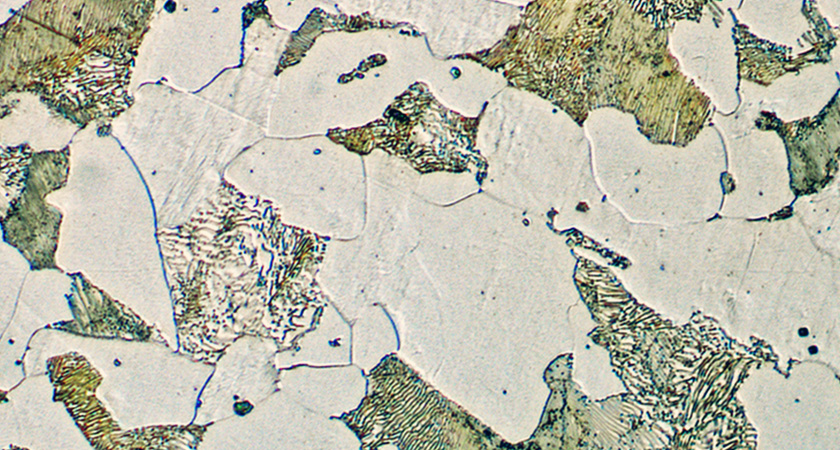

- Corrosion damage assessment

- Leak-before-break assessment

- Assessment of shell deformation damage

- Recommendations for maintenance, inspection, and integrity operating windows

- Identification of critical areas reduces inspection scope, thereby increasing efficiency and minimizing down time

- Tank reliability assessments categorize existing critical flaw sizes as safe or requiring immediate action

- Remaining life estimates provide reliable guidance in tank integrity and determine appropriate inspection plans

- Hydrostatic test exemptions can save the cost and logistics of water obtainment, proper disposal, and multiple weeks of down time

- Edge settlement analysis prevents costly repairs such as tank jacking and floor replacement

- Tank farms and terminals

- Refining and chemical

- Syngas (e.g., ammonia production facilities)

- Distribution facilities

- Municipalities

- Pipeline storage terminals

- Hydrostatic test exemptions for atmospheric storage tanks following shell and/or floor repairs per API 653 Tank Inspection, Repair, Alteration, and Reconstruction

- Analysis of excessive settlement of Aboveground Storage Tanks

- FFS, including remaining life predictions, considering a wide range of damage mechanisms

- Corrosion damage assessment

- Leak-before-break assessment

- Assessment of shell deformation damage

- Recommendations for maintenance, inspection, and integrity operating windows

- Identification of critical areas reduces inspection scope, thereby increasing efficiency and minimizing down time

- Tank reliability assessments categorize existing critical flaw sizes as safe or requiring immediate action

- Remaining life estimates provide reliable guidance in tank integrity and determine appropriate inspection plans

- Hydrostatic test exemptions can save the cost and logistics of water obtainment, proper disposal, and multiple weeks of down time

- Edge settlement analysis prevents costly repairs such as tank jacking and floor replacement

- Tank farms and terminals

- Refining and chemical

- Syngas (e.g., ammonia production facilities)

- Distribution facilities

- Municipalities

- Pipeline storage terminals

Talk To an Expert

Do you want to discover more about Quest Integrity services and solutions for your company? Let us know about your project here.