Quest Integrity has extensive experience in solving plant equipment integrity problems through a combination of extensive practical understanding of plant operation and highly advanced models to simulate structural and material behavior. Our expertise spans process and syngas plants, as well as hydro, geothermal, fossil plants, pipelines, and more.

Structural and Mechanical Integrity Consulting

Expert-powered integrity analysis and improvement strategies from Quest Integrity

Talk To An Expert

Expert-powered integrity analysis and improvement strategies from Quest Integrity

Talk To An Expert

Service Highlights

Explore the features of Structural and Mechanical Integrity Consulting

Through a combination of broad practical experience and advanced finite element stress analysis and Fitness-for-Service (FFS) methods, we provide our customers with a complete set of storage tank integrity solutions. These solutions include hydrostatic test exemption, floor settlement analysis, repair compliance analysis, and fatigue and crack growth analysis performed in accordance with API 653 Tank Inspection, Repair, Alteration, and Reconstruction and API 579-1/ASME FFS-1 Fitness-for-Service.

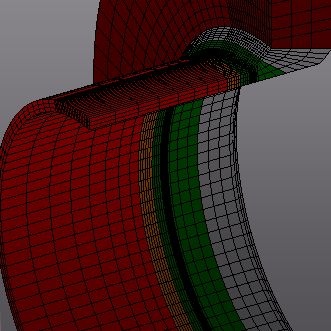

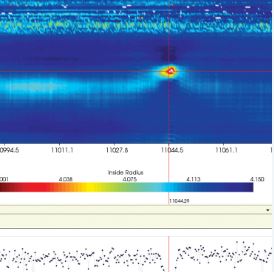

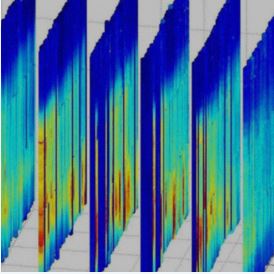

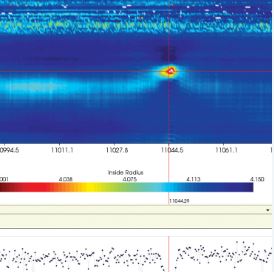

The probability of failure from pipeline dents can be accurately evaluated using an advanced strain dent calculator and subsequent dent assessment. Based on ultrasonic pipe scans, the assessment procedure can identify not only the exact location, size, and depth of individual dents, but also the severity of indentation. Mode of failure, such as cracking by cyclic fatigue or collapse due to excessive strain, is also evaluated as part of the assessment. The outcome of the dent assessment helps operators determine if repair is necessary.

Quest Integrity provides consultancy to operators of turbo machinery (e.g., gas, steam, and geothermal turbines) in both the power and oil and gas sectors, from large heavy industrial turbines to smaller aero-derivative gas turbine units. Our services include root cause analysis and failure investigation, condition assessment, life assessment, life management of parts, advanced inspection, and litigation support. We provide support independent of the original equipment manufacturer (OEM) and administer impartial counsel on OEM recommendations.

Quest Integrity offers 30+ years of expertise in the hydro power industry, conducting major failure investigations as well as predictive integrity assessments of penstock, runners, inlet valves, and head covers. Predictive integrity assessment helps operators develop an inspection criterion with respect to acceptable defect sizes prior to scheduled turnarounds to avoid delays in identifying and managing defects at the same time.

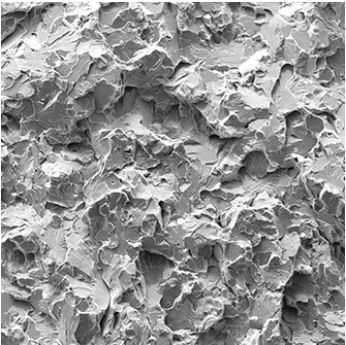

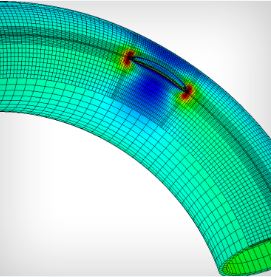

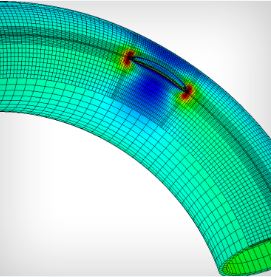

Fracture mechanics simulation is comprised of advanced, robust modeling of complex cracking problems. This approach removes many of the simplistic conservative assumptions that are typical of standard fracture mechanics assessments.

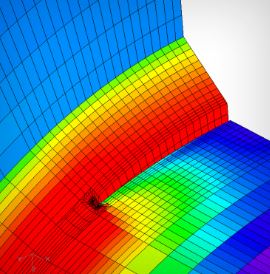

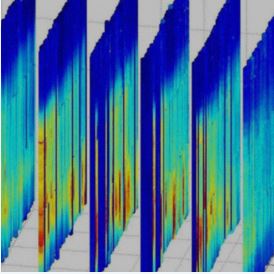

Quest Integrity has the largest creep testing facility in the southern hemisphere and offers decades of high-temperature material and metallurgical expertise. Combining the outcome from creep testing with advanced Finite Element creep analysis enables us to calculate damage for high-temperature components to determine an accurate remaining creep life.

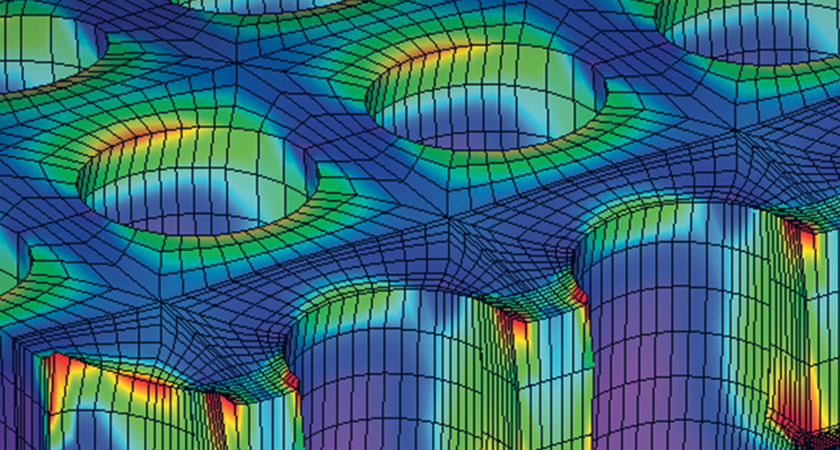

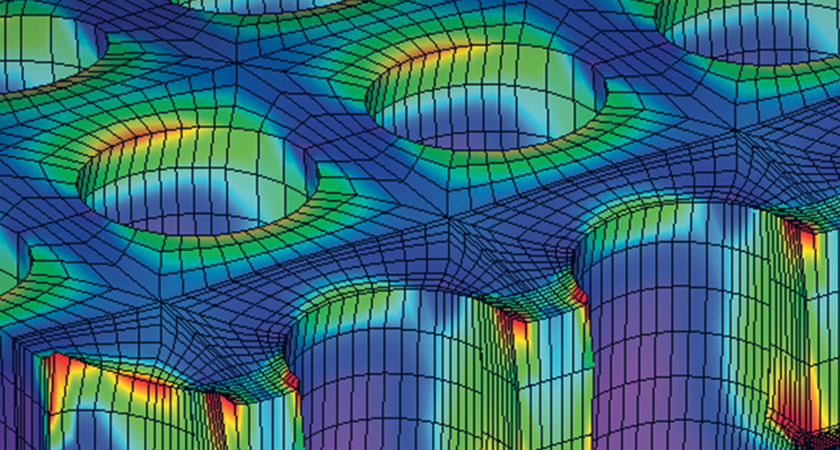

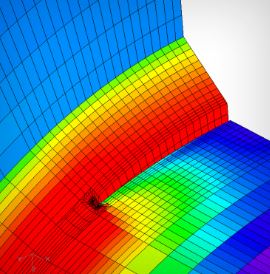

Quest Integrity engineers are capable of simulating equipment under highly complex loading condition and material behavior using computational mechanics and advanced FEA. Our industry expertise includes weld simulation, effectiveness of post-weld heat treatment, and creep relaxation behavior in equipment operated at high temperatures.

With FFS experts in the United States, Australia, and New Zealand, Quest Integrity is suited to support plant shutdowns 24/7. Our global engineering presence and consistent assessment procedures enable us to expedite critical assessment of flaws discovered during turnarounds that might otherwise cause costly delays.

Our technical experts host frequent training courses around the world to assist in assessing critical assets to determine condition and extend asset life.

Through a combination of broad practical experience and advanced finite element stress analysis and Fitness-for-Service (FFS) methods, we provide our customers with a complete set of storage tank integrity solutions. These solutions include hydrostatic test exemption, floor settlement analysis, repair compliance analysis, and fatigue and crack growth analysis performed in accordance with API 653 Tank Inspection, Repair, Alteration, and Reconstruction and API 579-1/ASME FFS-1 Fitness-for-Service.

The probability of failure from pipeline dents can be accurately evaluated using an advanced strain dent calculator and subsequent dent assessment. Based on ultrasonic pipe scans, the assessment procedure can identify not only the exact location, size, and depth of individual dents, but also the severity of indentation. Mode of failure, such as cracking by cyclic fatigue or collapse due to excessive strain, is also evaluated as part of the assessment. The outcome of the dent assessment helps operators determine if repair is necessary.

Quest Integrity provides consultancy to operators of turbo machinery (e.g., gas, steam, and geothermal turbines) in both the power and oil and gas sectors, from large heavy industrial turbines to smaller aero-derivative gas turbine units. Our services include root cause analysis and failure investigation, condition assessment, life assessment, life management of parts, advanced inspection, and litigation support. We provide support independent of the original equipment manufacturer (OEM) and administer impartial counsel on OEM recommendations.

Quest Integrity offers 30+ years of expertise in the hydro power industry, conducting major failure investigations as well as predictive integrity assessments of penstock, runners, inlet valves, and head covers. Predictive integrity assessment helps operators develop an inspection criterion with respect to acceptable defect sizes prior to scheduled turnarounds to avoid delays in identifying and managing defects at the same time.

Fracture mechanics simulation is comprised of advanced, robust modeling of complex cracking problems. This approach removes many of the simplistic conservative assumptions that are typical of standard fracture mechanics assessments.

Quest Integrity has the largest creep testing facility in the southern hemisphere and offers decades of high-temperature material and metallurgical expertise. Combining the outcome from creep testing with advanced Finite Element creep analysis enables us to calculate damage for high-temperature components to determine an accurate remaining creep life.

Quest Integrity engineers are capable of simulating equipment under highly complex loading condition and material behavior using computational mechanics and advanced FEA. Our industry expertise includes weld simulation, effectiveness of post-weld heat treatment, and creep relaxation behavior in equipment operated at high temperatures.

With FFS experts in the United States, Australia, and New Zealand, Quest Integrity is suited to support plant shutdowns 24/7. Our global engineering presence and consistent assessment procedures enable us to expedite critical assessment of flaws discovered during turnarounds that might otherwise cause costly delays.

Our technical experts host frequent training courses around the world to assist in assessing critical assets to determine condition and extend asset life.

Talk To an Expert

Do you want to discover more about Quest Integrity services and solutions for your company? Let us know about your project here.