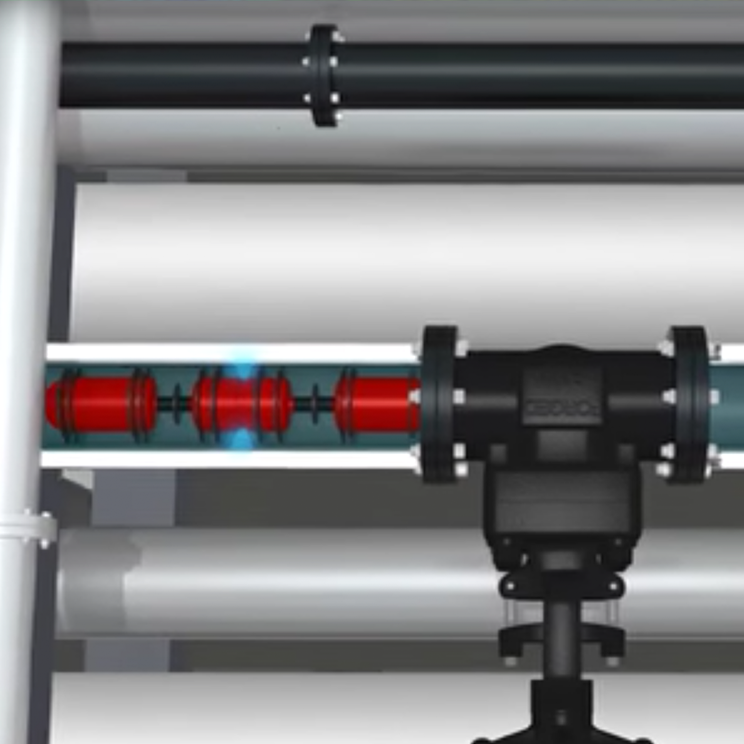

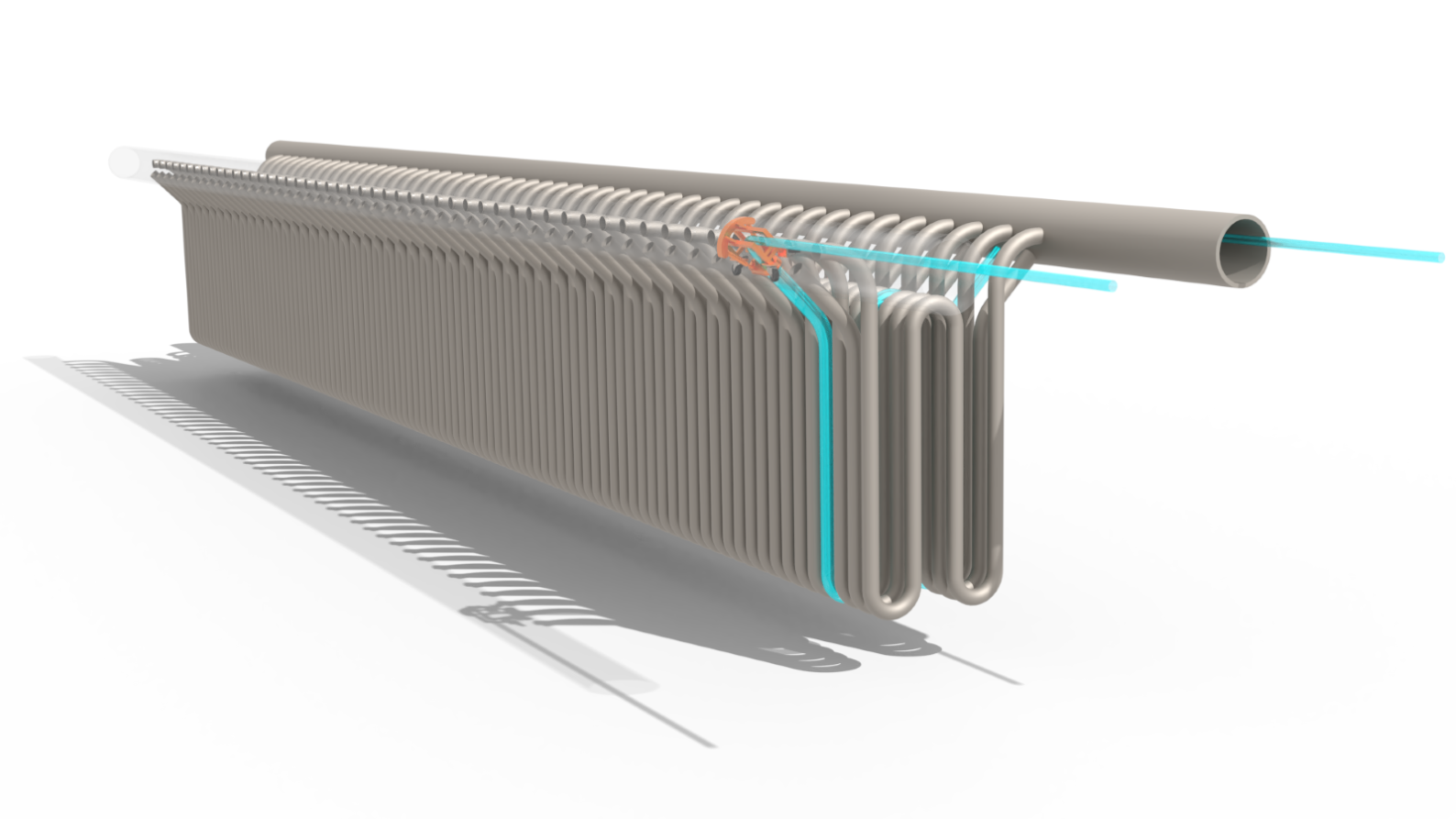

Integrity management programs that include process or plant piping are challenging to implement and accurately maintain when applying traditional NDT methods. Quest Integrity provides a comprehensive solution which includes intelligent pigging technology and advanced engineering assessment capabilities. InVista™ is used to inspect piping systems fabricated from austenitic, ferritic and some non-metallic materials, from 2 inches in diameter, including varying pipe thicknesses. It addresses specific challenges, such as inspection of short piping lengths in complex configurations, buried or insulated piping, elevated piping or piping systems which have limited space for launching/receiving the instrument.

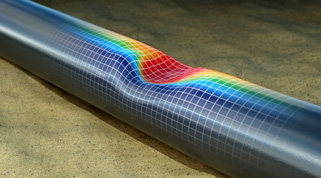

Following the inspection and generation of the preliminary inspection report, the data is analyzed to identify many damage mechanisms outlined in API 571 and ASME such as wall loss degradation (e.g. corrosion, erosion, pitting, fretting, etc.) and deformation damage (e.g. denting, bulging and ovality). Inspection reports are quickly delivered for each inspection project and tailored to satisfy API 570 and API 574 process piping and system component inspection codes.

Based on the inspection results, an advanced engineering assessment using the company’s proprietary software, Streamline™, calculates the remaining life and fitness-for-service of the piping in accordance to the API 579 / ASME FFS-1 standards.